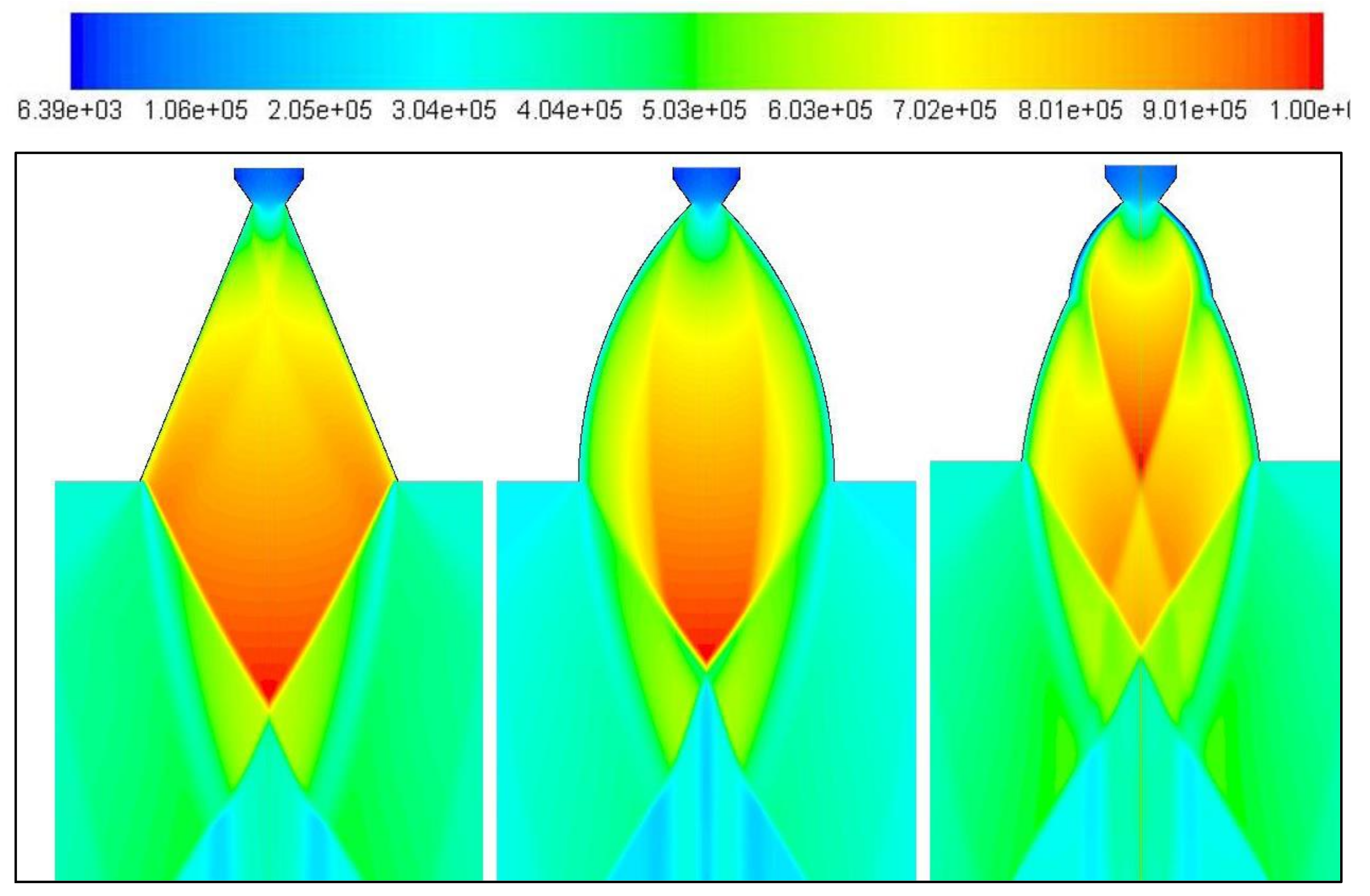

The influence of the force scheme parameter and the dimensionless relaxation time on the thermodynamic consistency of the model is analyzed. The accuracy of the model is verified by the Maxwell construction, Laplace law, and Rayleigh–Plesset equation. In this paper, we present a modified three-dimensional multi-relaxation-time pseudo-potential model for large density ratio multiphase phenomena. Studying the flow characteristics of bubbles in a narrow gap is an important problem related to bearing cavitation and gas–liquid two-phase flow. This work intends to provide references to cavitation control and energy consumption optimization in piping systems using a perforated plate. Additionally, increased stages of perforated plate resulted in a multi-stage stepped energy drop in throttling orifices, and lead to obvious suppression of the cavitation. Results showed that the contribution to energy loss generated from orifice outlet was relatively larger than the inlet and that the degree and rate of energy variation deceased with the increasing stages during the flow in multi-stage models. The parameters of energy ratio and energy gradient were developed to effectively evaluate the degree and rate of flow energy variation. In this study, the characteristics of energy transfer and loss of cavitation flow with various pressure ratios in single and multi-stage perforated plates were numerically studied. The existing design and previous studies largely paid little attention to the characteristics of flow energy variation, resulting in severe performance issues and energy consumption. The characteristics of flow energy transfer and loss in perforated plates have a significant impact on its piping systems. Perforated plates are prevalently used in various integrated energy systems for flow restriction, vibration, and noise reduction.

0 kommentar(er)

0 kommentar(er)